Haa Haa, I don't get excited about much but these engines are indeed impressive. The motor in Pete's vid is slinging that 34x12 prop pretty darn good. Pete can you get us a weight on your 34x12 prop. The thrust numbers seem a bit optimistic but maybe these little engines have enough torque to make it happen.

I'd love to throw a 34x10 P-tip on there and see what numbers pop up. I'm thinking it would be better to utilize a lighter-less pitch prop that lets the engine turn up a bit more revs (if it could take it). If that 6.5 engine could turn a 34x10 P-tip at 4800+ I would get really excited.

I have a 34x12 wood prop that looks like Petes and it's really heavy 1lb 13oz. The carbon 34x10 P-tip in comparison weighs in at 1lb 2oz. The light Clark at only 13oz and Bi-props at 1lb 3oz (together).

ser 3 nacelles

23 posts

• Page 2 of 3 • 1, 2, 3

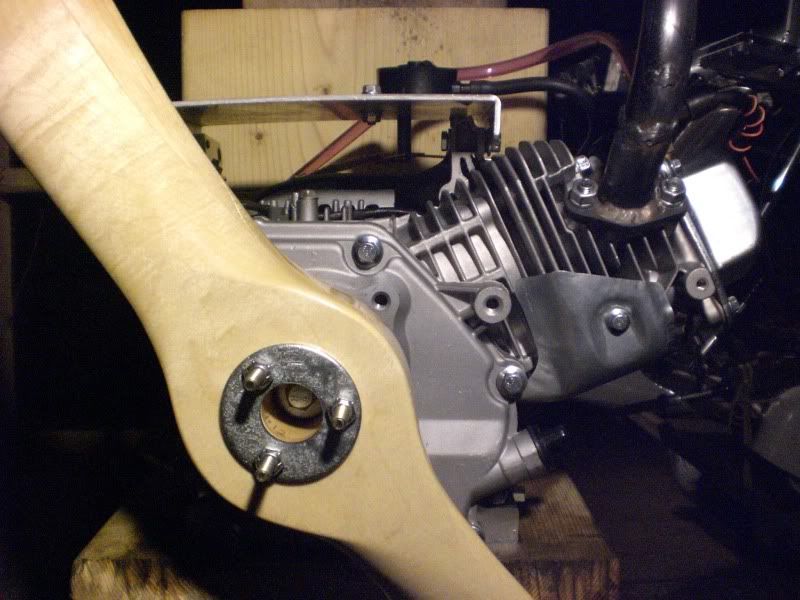

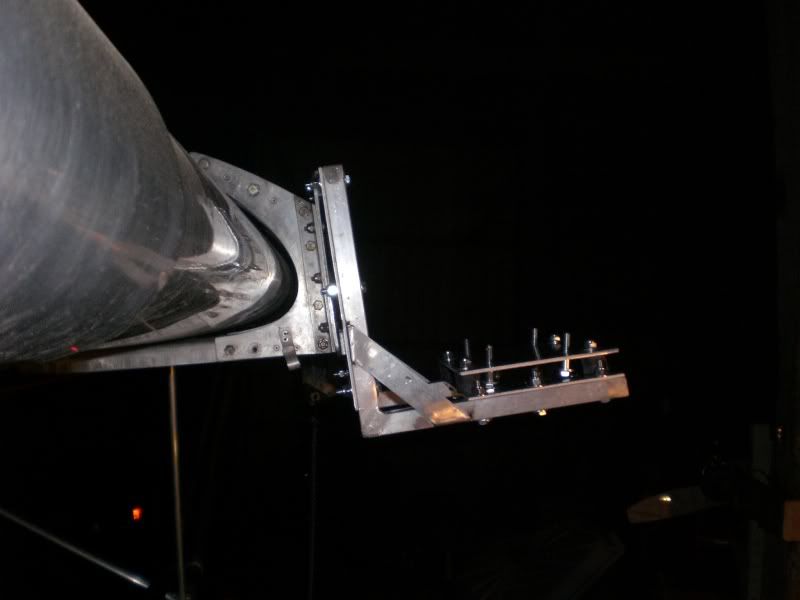

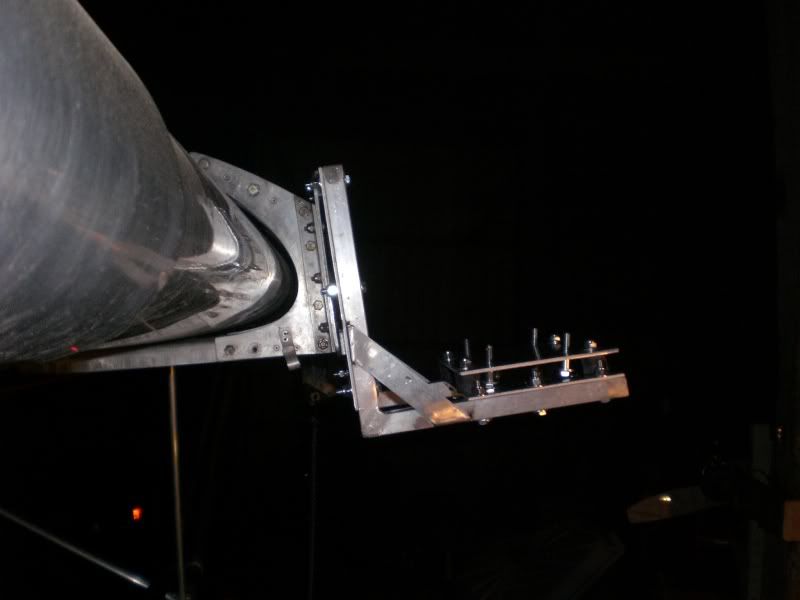

Here are some more of the motor mounts.

Here is the link to the Youtube vid.

http://www.youtube.com/watch?v=vPCWv61qWgI

Here is the link to the Youtube vid.

http://www.youtube.com/watch?v=vPCWv61qWgI

- peter

- Popular Lazair Member

- Posts: 80

- Joined: Fri Sep 22, 2006 9:10 am

- Location: Harriston Ont Can

Hi Shannon...On the bathroom scales the motor weighs 28lbs as you see it,...the parts to make the motor mounts , including the prop and hub and 4- 3/4 x 1 in rubber isolators but not including the muffler, or the handfull on bolts to put it together weighed almost 5 lbs....the prop will be close to 2 lbs I think.....With the muffler off the nacelle, I'll be close to the same weight as the rotax setup I reckon....this whole setup has worked out far lighter than I hoped....probably end up ariond 35lbs.

Going by the given, the NR motor turns the 31x12 Clark prop at 5050 ....according to the static thrust calculator this takes 9.6 hp and gives 68.9 lbs thrust...the rotax turn this prop at 5300....5000 rpm is too fast for these motors without billet rods and flywheels and that costs another 200 dolars...these clones are torquey engines, and produce far more power at lower rpms...I aimed for a prop that would top out at 4200 or so and was surprised to see the rpm come up over 4400 with the 34x12...If the 31x12 figures are true, then the same chart says to drive a 34x12 at 4450 takes 9.6 hp and gives 77.45 static thrust...note the increase in thrust...that's a massive amount of get up and go if true..

I'm encouraged enough by the results that I've ordered another engine...cost with upgrades is a bit over 300 bucks, but the kicker is the 150 or so to get it delivered....anyway nicely under 500 dollars Can for an engine that hopefully will give around the same performance as the rotax's but with all the advantages of the 4 strokes...should get 4 hours flying with reserve using the 5 gal tank.and no oil mixing too...bonus

Cheers.......Pete

Going by the given, the NR motor turns the 31x12 Clark prop at 5050 ....according to the static thrust calculator this takes 9.6 hp and gives 68.9 lbs thrust...the rotax turn this prop at 5300....5000 rpm is too fast for these motors without billet rods and flywheels and that costs another 200 dolars...these clones are torquey engines, and produce far more power at lower rpms...I aimed for a prop that would top out at 4200 or so and was surprised to see the rpm come up over 4400 with the 34x12...If the 31x12 figures are true, then the same chart says to drive a 34x12 at 4450 takes 9.6 hp and gives 77.45 static thrust...note the increase in thrust...that's a massive amount of get up and go if true..

I'm encouraged enough by the results that I've ordered another engine...cost with upgrades is a bit over 300 bucks, but the kicker is the 150 or so to get it delivered....anyway nicely under 500 dollars Can for an engine that hopefully will give around the same performance as the rotax's but with all the advantages of the 4 strokes...should get 4 hours flying with reserve using the 5 gal tank.and no oil mixing too...bonus

Cheers.......Pete

- peter

- Popular Lazair Member

- Posts: 80

- Joined: Fri Sep 22, 2006 9:10 am

- Location: Harriston Ont Can

call me the lazair.com critic: however:

with that method of mounting, you are putting any stress delivered on the front of that mount, multiplied by the distance to the nacelle mount where it meets the wing, directly on the mounting bolts.

a) please tell me you have incorporated the "long bolt" modification, rather than using the four teeny tiny AN3 bolts to hold that nacelle on

i would strongly recommend moving the shock mounts, to as they are on a standard nacelle, and hard mount the engine to your "shelf"

i would strongly recommend moving the shock mounts, to as they are on a standard nacelle, and hard mount the engine to your "shelf"

at least with the "sandwich" mounts between the vertical plate of the nacelle immediately in front of the wing, and the plate that forms the engine mount (vertically), any shock loads from landing are dampened through the mounts there. with your arrangement, any hard landing (shock loads) will have the entire weight of the engine transmitted through the arm of the nacelle to the mounting bolts. that is a LOT of torque, especially with a 35 pound engine setup. GA aircraft have engine mounts like this, mostly for turbine engines (long) but they also have welded cromoly engine mounts off a very large firewall riveted to the entire fuselage structure.

we have 4 tiny bolts that grab blind nuts on a 0.025" aluminum D shape held together with foam, glue and a handful of rivets.

be careful - i have no doubt it will fly fantastically, but beware the first hard landing. but i love the sound of the honda so far - following with great interest.

Tyler

with that method of mounting, you are putting any stress delivered on the front of that mount, multiplied by the distance to the nacelle mount where it meets the wing, directly on the mounting bolts.

a) please tell me you have incorporated the "long bolt" modification, rather than using the four teeny tiny AN3 bolts to hold that nacelle on

i would strongly recommend moving the shock mounts, to as they are on a standard nacelle, and hard mount the engine to your "shelf"

i would strongly recommend moving the shock mounts, to as they are on a standard nacelle, and hard mount the engine to your "shelf"

at least with the "sandwich" mounts between the vertical plate of the nacelle immediately in front of the wing, and the plate that forms the engine mount (vertically), any shock loads from landing are dampened through the mounts there. with your arrangement, any hard landing (shock loads) will have the entire weight of the engine transmitted through the arm of the nacelle to the mounting bolts. that is a LOT of torque, especially with a 35 pound engine setup. GA aircraft have engine mounts like this, mostly for turbine engines (long) but they also have welded cromoly engine mounts off a very large firewall riveted to the entire fuselage structure.

we have 4 tiny bolts that grab blind nuts on a 0.025" aluminum D shape held together with foam, glue and a handful of rivets.

be careful - i have no doubt it will fly fantastically, but beware the first hard landing. but i love the sound of the honda so far - following with great interest.

Tyler

-

JPXman - LazairNUT

- Posts: 627

- Joined: Sun Nov 02, 2003 10:15 pm

Hi Pete, wow you are really getting on with this project. I think you are serious.

OK here goes my ideas on things. You can pretty much disregard what I say here because this is your project, you are doing the hands-on, and testing. I'm just going to throw some things out there based on nothing but guessing and conjecture..haa haa. I do however have a 32x11 Clark and Catto 34x12 prop to physically look at. I've test run them both on the 185s. I understand the costs of actually buying and testing P-tips and/or other props. My only point is that it's all interesting to ponder at this stage.

First I have an idea you may be a bit over-propped with the GSC prop. In the air in a hard climb the engine may not have the torque to keep the props spinning up to speed. It will not be good if your engines choke down too much in flight. A P-tip looks like it would rest in the middle of the testing numbers. Just the physical size puts it in the middle. Your engines may be able to really hump through-out the flight envelope with a 34x10 prop. Additionally the P-tips weigh half of the GSC prop which could end up being a really important factor in regards to engine life.

Second the total weight seems really good. Do you think however that anything could be trimmed off the motor. I see lots of metal and things there that would be wonderful to get rid of in duplicate. Anything you can shave off is going to be a big help. You may not need to do any CG adjustment work in the end.

Third is the noise. What type of muffler arrangement are you planning. I saw somewhere what looked like a straight header with a Briggs muffler on the end. It was really cheap. I'll see if I can dig that up again. Here it is. http://www.geckermotorsports.com/ExhaustSystems.htm

Fourth. What's your take on using a Tillotson Carb ? Would that not be a good idea for some reason other than cost. Seems like the Tillotson would solve the problem of pulling the gas up from the tank. You could also get rid of the air-filters saving weight and maybe increasing power.

Sixth. Is there any way to re-mount the pull starters for L&R directional pull ?

OK so that's some of my thoughts on things so far. As I said don't read much into it as I clearly don't know what I'm talking about...Haa Haa !

Oh yeah your racing engine is the "Yellow Box Stock Project" correct ?

http://www.nr-racing.com/BSPEngines.htm

What is the shaft type, length, size and where did you source the prop hub ?

OK here goes my ideas on things. You can pretty much disregard what I say here because this is your project, you are doing the hands-on, and testing. I'm just going to throw some things out there based on nothing but guessing and conjecture..haa haa. I do however have a 32x11 Clark and Catto 34x12 prop to physically look at. I've test run them both on the 185s. I understand the costs of actually buying and testing P-tips and/or other props. My only point is that it's all interesting to ponder at this stage.

First I have an idea you may be a bit over-propped with the GSC prop. In the air in a hard climb the engine may not have the torque to keep the props spinning up to speed. It will not be good if your engines choke down too much in flight. A P-tip looks like it would rest in the middle of the testing numbers. Just the physical size puts it in the middle. Your engines may be able to really hump through-out the flight envelope with a 34x10 prop. Additionally the P-tips weigh half of the GSC prop which could end up being a really important factor in regards to engine life.

Second the total weight seems really good. Do you think however that anything could be trimmed off the motor. I see lots of metal and things there that would be wonderful to get rid of in duplicate. Anything you can shave off is going to be a big help. You may not need to do any CG adjustment work in the end.

Third is the noise. What type of muffler arrangement are you planning. I saw somewhere what looked like a straight header with a Briggs muffler on the end. It was really cheap. I'll see if I can dig that up again. Here it is. http://www.geckermotorsports.com/ExhaustSystems.htm

Fourth. What's your take on using a Tillotson Carb ? Would that not be a good idea for some reason other than cost. Seems like the Tillotson would solve the problem of pulling the gas up from the tank. You could also get rid of the air-filters saving weight and maybe increasing power.

Sixth. Is there any way to re-mount the pull starters for L&R directional pull ?

OK so that's some of my thoughts on things so far. As I said don't read much into it as I clearly don't know what I'm talking about...Haa Haa !

Oh yeah your racing engine is the "Yellow Box Stock Project" correct ?

http://www.nr-racing.com/BSPEngines.htm

What is the shaft type, length, size and where did you source the prop hub ?

- Shannon

- SHANNON

- Posts: 1084

- Joined: Thu Jan 15, 2004 10:05 pm

Hi Tyler and Shannon....thanks for taking interest in this project...any suggestions and ideas are more than welcome...I've done what you suggested with the mounts Tyler...Far far better mounting setup with the bushings on the back plate, and it eliminated a plate under the motor to boot....it looks better too .... I also ordered the long bolts today...I was always a bit uneasy with the original set up but it seems to hold up ok, and the bolts always stayed tight...had intended to do it last winter but now I'm commited...I think it was Shannon who posted the details on the long bolt mod back then...thanks guy...

Shannon, I debated between a 34x10 or a 34x12, and settled on the 12 pitch to keep the rpm down. I was hoping for wot around 4200, and I have better than 4400...these engines work better at lower rpm than the rotax's....I suspect I'll cruise around 4000...

I have a bit more tin to trim off the motor...the cooling fan will go plus the cooling shroud and the top plate...likely half a pound or so...I'm going to move the fuel pump to the back plate....I'm also going to replace the throttle cables and the gas lines which are still original while I'm at it....I'll hang it from the boom when I'm all done, but I think the c of g is not going to change much...It flys pretty level with the pod on.....Thanks Glen....

I found on my other test motor, a brigs muffler drops the rpm by about 50...I've ordered better mufflers with a 1 and 5/16 pipe...hopefully quieter and less restrictive .....by the way, the shaft size is 3/4 in x 2 3/8 with a 3/16 keyway

I'm going to stick with the Mikuni fuel pump...it appears able to lift the gas about 4 feet, which is a bit to spare...but the tillotsons are an option...I want to leave the air filters on because there are a lot flys and bugs on my strip, especially after I mow the grass.... really plasters the props.

The starters are easily turned to any position, I think in about 1 in increments if needed, so L R positioning will be no problem

All in all, I'm pretty optimistic so far...its going to be interesting to see how well the plane performs and please don't hesitate to give me any thoughts or ideas or criticism you may have...we're kind of breaking new ground here with these engines, and although I've got a bit of a handle on it, new eyes often see clearer

I weighed the bits and pieces this morn. on the hdwe store scale.

Motor mount and nacelle 6.75 lbs

Prop GSC 34x12 1.8 lbs

Hub Zeroerror racing .36 lbs

Crush plate .14 lbs

6.5 honda clone-NR racing 28. lbs

Have to add another pound or so for the muffler and brace, but it looks like the motor setup will be 38lbs , give or take a bit

. I'll get my son to take more pictures as I progress

Cheers.......Pete

Shannon, I debated between a 34x10 or a 34x12, and settled on the 12 pitch to keep the rpm down. I was hoping for wot around 4200, and I have better than 4400...these engines work better at lower rpm than the rotax's....I suspect I'll cruise around 4000...

I have a bit more tin to trim off the motor...the cooling fan will go plus the cooling shroud and the top plate...likely half a pound or so...I'm going to move the fuel pump to the back plate....I'm also going to replace the throttle cables and the gas lines which are still original while I'm at it....I'll hang it from the boom when I'm all done, but I think the c of g is not going to change much...It flys pretty level with the pod on.....Thanks Glen....

I found on my other test motor, a brigs muffler drops the rpm by about 50...I've ordered better mufflers with a 1 and 5/16 pipe...hopefully quieter and less restrictive .....by the way, the shaft size is 3/4 in x 2 3/8 with a 3/16 keyway

I'm going to stick with the Mikuni fuel pump...it appears able to lift the gas about 4 feet, which is a bit to spare...but the tillotsons are an option...I want to leave the air filters on because there are a lot flys and bugs on my strip, especially after I mow the grass.... really plasters the props.

The starters are easily turned to any position, I think in about 1 in increments if needed, so L R positioning will be no problem

All in all, I'm pretty optimistic so far...its going to be interesting to see how well the plane performs and please don't hesitate to give me any thoughts or ideas or criticism you may have...we're kind of breaking new ground here with these engines, and although I've got a bit of a handle on it, new eyes often see clearer

I weighed the bits and pieces this morn. on the hdwe store scale.

Motor mount and nacelle 6.75 lbs

Prop GSC 34x12 1.8 lbs

Hub Zeroerror racing .36 lbs

Crush plate .14 lbs

6.5 honda clone-NR racing 28. lbs

Have to add another pound or so for the muffler and brace, but it looks like the motor setup will be 38lbs , give or take a bit

. I'll get my son to take more pictures as I progress

Cheers.......Pete

- peter

- Popular Lazair Member

- Posts: 80

- Joined: Fri Sep 22, 2006 9:10 am

- Location: Harriston Ont Can

Peter,

It's very encouraging that you are pursuing this project. Weight is my biggest worry, but it's sounding like that may work out after all. Are you considering using the aftermarket aluminum flywheel? I think I read somewhere it cuts something like six pounds off the package weight. That sounds like the way to go if they are not budget busters. The billet connecting rod might be worth it too for piece of mind.

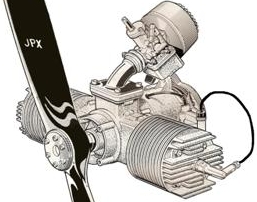

It appears that the 6.5 HP engine I bought at Harbor Freight for $100 on sale may be the same engine you are using. It is Model No. 66015 and is shown as being made/marketed by "Greyhound". The manual is here: http://www.harborfreight.com/manuals/66 ... /66015.pdf Actual displacement is listed as 196 cc. It looks just like yours. I believe it normally sells for $150-160 US, but I've seen it several times on sale for $129. HF has an e-mail coupon mailing and that's how I got mine for $100. I don't know if there are any outlets near you. Shipping sure has gotten expensive on heavier things lately!

It's been 25 years, but I remember Ultraflight engine mounts for the KFM twin cylinder engines using 7075 T6 metal "spring" mounts rather than the classic rubber mounts normally used by the factory. They certainly didn't offer any shock load relief to the wing spars on hard landings. I think the long bolt modification may be adequate. Your motor mount design uses rubber mounts in their proper arrangement - in shear (and compression). Using them in tension is actually the only configuration that their manufacturers DO NOT rate them for! Dale got away with it because the loads, when shared between all those mounts, were so small. When I designed my re-drives for the Pioneers, I used a much larger rubber mount, but located them closer together so they acted softer in shear.

I think you'll find that the more you point your exhausts upward, the lower the sound level will be on the ground and the less muffler you'll need to placate people.

I think you'll find that with the improved torque of four cycle engines, compared to similar HP two cycle engines, that you'll find more actual thrust. Also, if you can get the same torque at a lower rpm, you'll come out ahead too because of improved propeller efficiency. I remember when they replaced the prop on an old decrepit C150 that I used to fly in with a considerably longer used prop after a student ran it off the runway and put the prop in the dirt. Although the longer prop loaded down the engine by several hundred rpm, the improved prop efficiency and good engine torque still provided an equivalent climb rate!

Good luck on your project!

Chappy

It's very encouraging that you are pursuing this project. Weight is my biggest worry, but it's sounding like that may work out after all. Are you considering using the aftermarket aluminum flywheel? I think I read somewhere it cuts something like six pounds off the package weight. That sounds like the way to go if they are not budget busters. The billet connecting rod might be worth it too for piece of mind.

It appears that the 6.5 HP engine I bought at Harbor Freight for $100 on sale may be the same engine you are using. It is Model No. 66015 and is shown as being made/marketed by "Greyhound". The manual is here: http://www.harborfreight.com/manuals/66 ... /66015.pdf Actual displacement is listed as 196 cc. It looks just like yours. I believe it normally sells for $150-160 US, but I've seen it several times on sale for $129. HF has an e-mail coupon mailing and that's how I got mine for $100. I don't know if there are any outlets near you. Shipping sure has gotten expensive on heavier things lately!

It's been 25 years, but I remember Ultraflight engine mounts for the KFM twin cylinder engines using 7075 T6 metal "spring" mounts rather than the classic rubber mounts normally used by the factory. They certainly didn't offer any shock load relief to the wing spars on hard landings. I think the long bolt modification may be adequate. Your motor mount design uses rubber mounts in their proper arrangement - in shear (and compression). Using them in tension is actually the only configuration that their manufacturers DO NOT rate them for! Dale got away with it because the loads, when shared between all those mounts, were so small. When I designed my re-drives for the Pioneers, I used a much larger rubber mount, but located them closer together so they acted softer in shear.

I think you'll find that the more you point your exhausts upward, the lower the sound level will be on the ground and the less muffler you'll need to placate people.

I think you'll find that with the improved torque of four cycle engines, compared to similar HP two cycle engines, that you'll find more actual thrust. Also, if you can get the same torque at a lower rpm, you'll come out ahead too because of improved propeller efficiency. I remember when they replaced the prop on an old decrepit C150 that I used to fly in with a considerably longer used prop after a student ran it off the runway and put the prop in the dirt. Although the longer prop loaded down the engine by several hundred rpm, the improved prop efficiency and good engine torque still provided an equivalent climb rate!

Good luck on your project!

Chappy

- Chappy

- LazairNUT

- Posts: 330

- Joined: Wed Jan 28, 2004 9:57 pm

- Location: Northern Virginia, USA

Hi Bob... you know that idea about replacing the flywheel deserves a bit more thought...from a safety standpoint, I think it it's ok under 5000 rpm, but the weight saving factor is perhaps worth the the 200$ or so....these motors are longer....are going to sit a bit further ahead on the mounts than the rotax, by 2'' or so, compounding the C of G problem.....just might make the difference of not having to move the seat.... Another bonus would be a bit more HP freed up

These Chinese clones are the same as you are referring to. in Can they are readily available for around 140$ on sale...there are several differend manufacturers apparently, but the Karting boys seem to prefer the Yellow clones for their better quality.

My original thoughts for the mounts on the floor were based on allowing me to keep the weight back the 1'' depth of the bushings, and it's maybe ok, but I like the better cushioning of the back mounts even so I run my tires fairly slack.

One thing I should mention, is the fact that the prop shaft is offset from the motor mounts by 5/8 in to the left, which made me offset the motor mount on the wing plate by the same to keep the prop centered to the nacelle....this is going to place some additional torque on the bushings and nacelle bolts that I don't like...It will be another point to keep a close eye on....the long bolts will be a stronger attachment for sure.....5/8 isn't much and maybe the slightly different thrust wouldn't even be noticed except on an engine out, but I thought I'd better not take the chance

Fun and games....................Pete

These Chinese clones are the same as you are referring to. in Can they are readily available for around 140$ on sale...there are several differend manufacturers apparently, but the Karting boys seem to prefer the Yellow clones for their better quality.

My original thoughts for the mounts on the floor were based on allowing me to keep the weight back the 1'' depth of the bushings, and it's maybe ok, but I like the better cushioning of the back mounts even so I run my tires fairly slack.

One thing I should mention, is the fact that the prop shaft is offset from the motor mounts by 5/8 in to the left, which made me offset the motor mount on the wing plate by the same to keep the prop centered to the nacelle....this is going to place some additional torque on the bushings and nacelle bolts that I don't like...It will be another point to keep a close eye on....the long bolts will be a stronger attachment for sure.....5/8 isn't much and maybe the slightly different thrust wouldn't even be noticed except on an engine out, but I thought I'd better not take the chance

Fun and games....................Pete

- peter

- Popular Lazair Member

- Posts: 80

- Joined: Fri Sep 22, 2006 9:10 am

- Location: Harriston Ont Can

23 posts

• Page 2 of 3 • 1, 2, 3

Who is online

Users browsing this forum: No registered users and 40 guests